Christopher O’Connor has been working in the electrical, mechanical and engineering fields for over a decade.

Having specialized in fault diagnosis and repairs of manufacturing machinery, it became apparent that the biggest source of frustration for clients was the unexpected failure of a part or a machine.

The cost of the repair or part on the machine often pales into significance relative to the additional costs associated with the unexpected machinery down time, loss of production and additional costs in overtime in an effort to catch up.

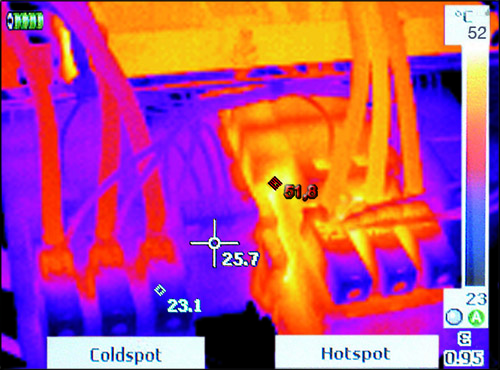

It was as a result of the above that in 2013 Lumineire was set up. Lumineire utilizes thermal imaging technology to essentially predict a part/component failure before it actually happens.

We bring innovative diagnostic and monitoring solutions into daily life through our thermal imaging systems, visible-light imaging systems, locator systems, measurement and diagnostic systems, and advanced failure detection systems.

Our services improve the way business perform, enhance employee safety and well-being, and increase energy efficiency which leads to multiple cost savings.

Lumineire adhere to the international standard ISO 18434-1.7